safety hazards app.vibtodo.com

Kworld Trend / safety hazards app.vibtodo.com

safety hazards app.vibtodo.com

10 Tips to Protect Yourself From Safety Hazards

10 Tips to Protect Yourself From Safety Hazards – Safety hazards are a threat to our daily lives, be it at home, work, or in public spaces. Accidents can occur at any time, causing injury, disability, or even death. However, it’s essential to take necessary precautions and preventive measures to avoid such hazards. Here are ten tips to protect yourself from safety hazards.

1. Identify Potential Hazards

The first step in protecting yourself from safety hazards is to identify potential dangers. Observe your surroundings and determine potential risks, such as slippery floors, loose wires, or sharp edges. Take note of any hazardous areas, equipment, or substances, and keep away from them.

2. Wear Appropriate Gear

Always wear appropriate protective gear when working in hazardous areas, such as construction sites or factories. This includes gloves, hard hats, safety goggles, earplugs, and respiratory masks, among others. The gear provides a barrier between you and potential hazards.

3. Keep a Safe Distance

When working with hazardous equipment, always maintain a safe distance. This includes keeping children and pets away from dangerous areas or equipment. Be cautious when operating heavy machinery, and ensure you are well-trained and licensed to do so.

4. Follow Safety Procedures

Follow safety procedures and guidelines when working with hazardous equipment, such as lock-out tag-out procedures or proper lifting techniques. Always read and understand safety instructions before operating equipment or handling hazardous substances.

5. Stay Alert

Stay alert and focused on your surroundings, especially when working in high-risk environments. Avoid distractions, such as mobile devices or loud music, that can compromise your safety. Also, be aware of other people’s actions and movements in your surroundings.

6. Properly Store Hazardous Substances

Properly store hazardous substances, such as chemicals or flammable liquids, in designated areas away from high-traffic zones or heat sources. Ensure the containers are appropriately labeled and tightly sealed to prevent accidental spills or leaks.

7. Keep Emergency Equipment Accessible

Always keep emergency equipment, such as fire extinguishers, first aid kits, or safety showers, accessible in case of an emergency. Know the location and proper use of the equipment and regularly check them for functionality.

8. Report Safety Hazards

Report safety hazards to the appropriate authorities, such as your employer or safety officer. This includes broken equipment, faulty wiring, or any potential danger that requires immediate attention. Never ignore safety hazards as they can cause harm to yourself and others.

9. Take Breaks

Take regular breaks to avoid fatigue, which can compromise your safety. This is especially important when operating heavy machinery or working in high-risk environments that require your attention and focus. Rest when you feel tired, and avoid pushing yourself beyond your limits.

10. Stay Educated

Stay educated on safety hazards and preventive measures by attending training sessions or workshops. This includes first aid, fire safety, or emergency response training. Stay updated on safety procedures and guidelines to ensure your safety and that of others.

In conclusion, protecting yourself from safety hazards requires awareness, preparedness, and caution. Identify potential hazards, wear appropriate protective gear, follow safety procedures, and stay alert. Properly store hazardous substances, keep emergency equipment accessible, and report safety hazards when necessary. Take breaks when needed, and stay educated on safety hazards and preventive measures. By following these ten tips, you can protect yourself from safety hazards and ensure a safer environment for everyone. safety hazards app.vibtodo.com

11 Safety Measures to Ensure a Safer Construction Site

Construction sites are undoubtedly dangerous places, with many hazards that can cause serious injury or even death.

It is essential to take steps to ensure that workers are safe while on the job. Implementing safety measures can help prevent accidents, reduce risks, and create a safer working environment.

In this article, we will discuss 11 safety measures that can be taken to ensure a safer construction site.

1. Conduct Regular Safety Training

The importance of regular safety training cannot be overstated. All workers should be trained on the potential hazards of the job and how to prevent accidents. It is also essential to provide refresher courses on a regular basis, as new hazards may arise over time.

2. Wear Proper Personal Protective Equipment (PPE)

PPE such as hard hats, safety glasses, gloves, and steel-toed boots can protect workers from head injuries, eye injuries, hand injuries, and foot injuries. Employers should provide workers with the appropriate PPE and ensure that it is worn at all times.

3. Implement a Fall Protection Plan

Falls are a leading cause of injury on construction sites. A fall protection plan should be implemented to ensure that workers are protected from falls. This plan should include the use of guardrails, safety nets, and harnesses.

4. Conduct Regular Inspections

Regular inspections should be conducted to identify potential hazards and ensure that equipment is functioning correctly. Any issues found should be addressed immediately to prevent accidents. safety hazards app.vibtodo.com

5. Secure the Site

Construction sites should be secured to prevent unauthorized access. This can help reduce the risk of theft, vandalism, and accidents caused by non-workers. Fencing, gates, and signage can be used to secure the site.

6. Use Proper Lighting

Proper lighting is essential for ensuring that workers can see potential hazards and operate equipment safely. This is especially important in areas where work is being done at night or in low-light conditions.

7. Control Traffic

Traffic can pose a significant risk to workers on construction sites. To reduce this risk, traffic should be controlled through the use of barricades, traffic cones, and signs. Workers should also be trained on how to navigate traffic safely.

8. Use Proper Signage

Proper signage can help prevent accidents by alerting workers to potential hazards. Signs should be used to indicate the location of first aid kits, emergency exits, and other important information. safety hazards app.vibtodo.com

9. Ensure Proper Equipment Maintenance

Equipment that is not properly maintained can be dangerous to workers. Regular maintenance and inspections should be conducted to ensure that equipment is functioning correctly and does not pose a risk to workers.

10. Use Proper Lifting Techniques

Improper lifting techniques can cause serious back injuries. Workers should be trained on proper lifting techniques and provided with equipment such as dollies and forklifts to assist with heavy lifting.

11. Encourage Communication

Encouraging communication between workers can help prevent accidents. Workers should be trained on how to communicate effectively and encouraged to speak up if they see a potential hazard.

In conclusion, implementing safety measures is essential for ensuring a safer construction site. Regular safety training, the use of proper PPE, fall protection plans, regular inspections, site security, proper lighting, traffic control, proper signage, equipment maintenance, proper lifting techniques, and encouraging communication between workers are all important steps that can be taken to reduce the risk of accidents and create a safer working environment.

9 Differences Between Mobile Cranes and Tower Cranes

9 Differences Between Mobile Cranes and Tower Cranes – Cranes are a vital tool in the construction industry. They help in lifting and moving heavy loads, making it easier to construct tall buildings and structures. There are two main types of cranes used in construction: mobile cranes and tower cranes. Both have unique features that make them suitable for different jobs. In this article, we will explore the nine main differences between mobile cranes and tower cranes.

Cranes have been used in construction for centuries, and as technology has advanced, so has their capabilities. Mobile cranes and tower cranes are two of the most commonly used types of cranes in construction today. They have different features that make them ideal for different tasks, and in this article, we will explore their differences.

Definition of Mobile Cranes and Tower Cranes | safety hazards app.vibtodo.com

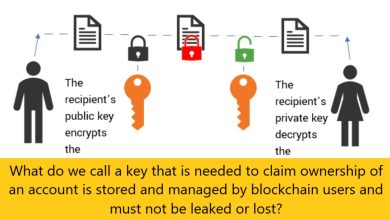

Before we dive into the differences between mobile cranes and tower cranes, it’s essential to understand what they are. A mobile crane is a type of crane that is mounted on a mobile platform, such as a truck or a crawler. It can move from one location to another quickly and easily. On the other hand, a tower crane is a type of crane that is fixed in place and is used for tall buildings and structures. It has a long vertical mast with a horizontal jib that rotates.

1. Mobility

One of the primary differences between mobile cranes and tower cranes is mobility. Mobile cranes are highly mobile, which means they can be easily moved from one job site to another. They are designed to be transported on the road and can quickly get to their destination. Tower cranes, on the other hand, are fixed in place and cannot be easily moved. They are typically assembled on-site and cannot be disassembled until the job is completed.

2. Height

Another significant difference between mobile cranes and tower cranes is their height. Mobile cranes are typically smaller than tower cranes and can reach heights of up to 300 feet. Tower cranes, on the other hand, can reach heights of up to 1,000 feet or more. This makes them ideal for tall buildings and structures where a lot of lifting needs to be done at great heights.

3. Size

Mobile cranes are generally smaller and more compact than tower cranes. This makes them ideal for jobs where space is limited, and there is not enough room for a larger crane. Tower cranes, on the other hand, are more massive and take up a lot of space. This makes them ideal for jobs where there is enough space to accommodate a larger crane.

4. Weight Capacity

Another difference between mobile cranes and tower cranes is their weight capacity. Mobile cranes typically have a lower weight capacity than tower cranes. This means they are suitable for smaller jobs that require less lifting. Tower cranes, on the other hand, have a much higher weight capacity and are suitable for larger jobs that require heavy lifting.

5. Set-Up Time

Mobile cranes are designed to be set up quickly, which means they can be ready to use in a short amount of time. Tower cranes, on the other hand, take much longer to set up. They require a lot of planning and preparation before they can be assembled on-site. safety hazards app.vibtodo.com

6. Operating Range

Mobile cranes typically have a smaller operating range than tower cranes. This means that they are suitable for jobs where the load needs to be moved a short distance. Tower cranes, on the other hand, have a much larger operating range and can move loads over a much greater distance.

7. Weather Limitations

Mobile cranes are more weather-dependent than tower cranes. They are more affected by wind and rain and cannot operate in extreme weather conditions. Tower cranes, on the other hand, are designed to withstand extreme weather conditions and can operate in almost any weather.

8. Cost

The cost of using a mobile crane or a tower crane is significantly different. Mobile cranes are generally cheaper to use than tower cranes. This is because they are smaller and have a lower weight capacity. Tower cranes, on the other hand, are more expensive to use due to their larger size, higher weight capacity, and longer set-up time.

9. Usage

Mobile cranes are ideal for smaller jobs that require less lifting, such as moving equipment or materials around a construction site. They are also suitable for jobs where space is limited. Tower cranes, on the other hand, are ideal for taller buildings and structures where a lot of lifting needs to be done at great heights.

Conclusion

In conclusion, mobile cranes and tower cranes have different features that make them suitable for different jobs. Mobile cranes are highly mobile, smaller, and have a lower weight capacity, making them ideal for smaller jobs that require less lifting. Tower cranes, on the other hand, are fixed in place, larger, have a higher weight capacity, and are suitable for larger jobs that require heavy lifting at great heights.