Revolutionizing manufacturing efficiency with erp software solutions duniacm.com

Kworld Trend / Revolutionizing manufacturing efficiency with erp software solutions duniacm.com

Are you tired of dealing with the inefficiencies and headaches that come with your manufacturing company’s procurement process? Look no further than ERP software! With this powerful tool, you can revolutionize the way your company handles procurement.

In this blog post, we’ll explore how ERP software can transform your procurement processes, the different types available for the manufacturing industry, and case studies of successful implementations. Get ready to streamline your operations and boost productivity with ERP software for manufacturing companies!

In this article, we will discuss the benefits of using ERP manufacturing software and how it can help your business thrive.

Revolutionizing manufacturing efficiency with erp software solutions duniacm.com

In today’s fast-paced business environment, manufacturers need efficient and reliable solutions to manage their operations. Enterprise Resource Planning (ERP) software has emerged as a popular choice for manufacturing companies to streamline their business processes, improve productivity, and increase profitability.

ERP software provides a comprehensive solution for managing all aspects of a manufacturing operation, from inventory and supply chain management to production planning and scheduling.

Procurement processes in the manufacturing industry can be complex and time-consuming. Many companies still rely on manual processes that are prone to errors, delays, and inconsistencies. This approach often leads to inefficiencies that impact productivity, profitability, and customer satisfaction.

One of the major challenges is managing multiple vendors and suppliers while ensuring compliance with quality standards. Manual procurement processes require a significant amount of paperwork, communication, and coordination between departments, which results in longer lead times for purchases.

Furthermore, without real-time visibility into inventory levels or supplier performance metrics like delivery time or quality standards adherence makes it challenging to make informed decisions about when or what to order. This lack of data can cause stockouts or excess inventory resulting from over-ordering.

In summary, these inefficiencies affect not just your company’s bottom line but also its reputation among customers who expect timely deliveries of high-quality products at competitive prices. Fortunately! ERP software offers an effective solution by automating procurement-related tasks while providing valuable insights into supplier performances allowing manufacturers to save money while increasing efficiency.

What is ERP Manufacturing Software?

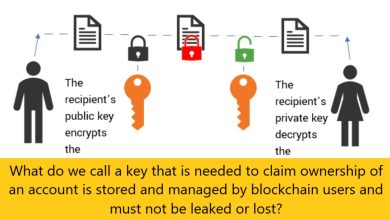

ERP Manufacturing Software is a software system that helps manufacturers manage their operations by integrating all business processes into one central system. This software provides a real-time view of the manufacturing process, enabling businesses to make informed decisions based on accurate data.

ERP manufacturing software typically includes modules for supply chain management, inventory management, production planning, scheduling, quality control, and financial management.

These modules are designed to work together seamlessly, providing a comprehensive view of the entire manufacturing process.

Introduction to Predictive Maintenance

Predictive maintenance is an advanced methodology that leverages data analytics, machine learning, and IoT technologies to anticipate equipment failures before they occur. Predictive maintenance allows businesses to continuously monitor machinery’s condition and performance, scheduling maintenance activities based on actual equipment conditions instead of predetermined schedules or reactive measures.

This approach has numerous advantages, including reduced downtime, increased efficiency, and lower maintenance costs. In the context of the chemical manufacturing industry, predictive maintenance is an essential component of a modern, Intelligent ERP system, helping companies stay ahead of the competition and maintain a seamless production process.

The Role of ERP Systems in Chemical Manufacturing

An ERP system for Chemical Manufacturing is a comprehensive software solution that integrates all aspects of a chemical manufacturing business, from production and inventory management to financial planning and customer relationship management. An ERP system helps chemical manufacturers streamline their operations, enhance decision-making, and improve overall efficiency by providing a centralized platform for managing information and resources.

Key features of an ERP system for Chemical Manufacturing include:

- Production planning and scheduling

- Inventory and warehouse management

- Quality control and regulatory compliance

- Sales and distribution management

- Procurement and supply chain management

- Financial management and reporting

- Customer relationship management

Benefits of Using ERP Manufacturing Software

There are many benefits to using ERP manufacturing software, including:

- Improved Productivity: ERP software streamlines processes and reduces manual labor, allowing manufacturers to focus on more value-added activities. By automating processes such as inventory management and production scheduling, ERP software helps manufacturers optimize their resources and improve productivity.

- Increased Efficiency: ERP software provides a centralized platform for managing all business processes, which reduces the risk of errors and duplication. This enables manufacturers to operate more efficiently and effectively, resulting in better customer service and increased profitability.

- Better Inventory Management: ERP software provides real-time visibility into inventory levels, enabling manufacturers to optimize their stock levels and reduce waste. This helps manufacturers avoid stock-outs and overstocking, which can both negatively impact their bottom line.

- Improved Supply Chain Management: ERP software provides end-to-end supply chain visibility, allowing manufacturers to manage their suppliers and logistics more effectively. This results in a more efficient and streamlined supply chain, which can help manufacturers reduce costs and improve customer satisfaction.

- Enhanced Quality Control: ERP software enables manufacturers to monitor their production processes in real-time, which helps identify and address quality issues before they become major problems. This results in higher-quality products and increased customer satisfaction.

How to Choose the Right ERP Manufacturing Software

Choosing the right ERP manufacturing software can be a daunting task. There are many factors to consider, including the software’s features, pricing, and support. Here are some key considerations when selecting an ERP manufacturing software solution:

- Features: Look for an ERP software solution that includes all the features you need to manage your manufacturing operations effectively. This may include modules for inventory management, production planning, scheduling, supply chain management, and quality control.

- Scalability: Choose an ERP software solution that can grow with your business. This means that the software should be able to handle an increasing number of users and transactions as your business expands.

- Integration: Look for an ERP software solution that can integrate with your existing systems, such as accounting software or customer relationship management (CRM) software. This can help streamline processes and reduce the risk of errors.

- User-Friendliness: The ERP software solution should be user-friendly and easy to use. This can help reduce training time and ensure that all users can access the system without difficulty.

- Support: Choose an ERP software solution that offers robust support, including training and technical support. This can help ensure that you get the most out of the software and that any issues are quickly resolved.

Cont

ERP manufacturing software can help manufacturers streamline their operations, reduce costs, and increase profitability.

By providing real-time visibility into all aspects of the manufacturing process, ERP software enables manufacturers to make informed decisions based on accurate data, improving efficiency and productivity.

Additionally, ERP software can enhance inventory management, supply chain management, and quality control, resulting in higher-quality products and better customer service.

When selecting an ERP manufacturing software solution, it’s important to consider the software’s features, scalability, integration capabilities, user-friendliness, and support. By choosing the right ERP software solution, manufacturers can effectively manage their operations and achieve their business goals.

ERP manufacturing software is a powerful tool that can help manufacturers optimize their operations and increase profitability.

As the manufacturing industry continues to evolve, ERP software will become increasingly essential for businesses that want to stay competitive and thrive in today’s fast-paced business environment. With the right ERP software solution in place, manufacturers can effectively manage their operations and achieve success in the long term.

Furthermore, the adoption of ERP manufacturing software can also lead to a more sustainable business operation.

Optimizing Revolutionizing manufacturing efficiency with erp software solutions

By optimizing resource utilization and minimizing waste, manufacturers can reduce their environmental impact and contribute to a more sustainable future.

In addition to the benefits mentioned above, ERP software can also help manufacturers stay compliant with industry regulations and standards. With modules designed specifically for quality control and compliance management, manufacturers can ensure that their products meet all necessary requirements.

Overall, the advantages of implementing ERP manufacturing software are significant and far-reaching. By automating and streamlining business processes, manufacturers can increase efficiency, reduce costs, improve quality, and enhance customer service. As a result, businesses can experience higher profitability, growth, and long-term success.

ERP manufacturing software is a powerful tool that can help manufacturers optimize their operations, achieve sustainability goals, and stay competitive in the market.

By carefully selecting the right software solution and implementing it effectively, manufacturers can reap the benefits of ERP software and thrive in today’s fast-paced business environment.

It’s worth noting that the implementation of ERP manufacturing software is not a one-time project but an ongoing process that requires ongoing maintenance, support, and updates.

Last

Therefore, businesses should carefully consider their resources and capabilities. Before embarking on an ERP implementation project. It’s also essential to involve all relevant stakeholders, such as employees, vendors, and customers. In the process to ensure a smooth transition and successful adoption of the software.

Finally, businesses should also consider the potential challenges that come with ERP implementation. Such as data migration, customization, and user adoption. It’s important to have a clear plan in place to address these challenges and ensure that the software meets the specific needs of the business.

Conclusion

In conclusion, ERP manufacturing software is a powerful solution that can help manufacturers. Optimizing their operations, achieve sustainability goals, and stay competitive in the market.

However, it’s essential to carefully evaluate the software’s features, scalability, integration capabilities. And the user-friendliness, and support, and to consider the potential challenges associated with implementation.

With the right ERP software solution in place, manufacturers can streamline their operations. Reducing costs, improve quality, and achieve long-term success. Revolutionizing manufacturing efficiency with erp software solutions